The ultra competitive world of packing and labelling today, means that products need to stand out against the competition, and catch the eye within seconds. This has meant the increasing popularity of special effects and finishes that not only have ‘shelf appeal’, but that also encourage the consumer to pick up the product – and importantly, buy.

CyanX has strong and long-standing relationships with leading manufacturers and suppliers in the industry to help its customers add value, and to be more creative, efficient, and productive.

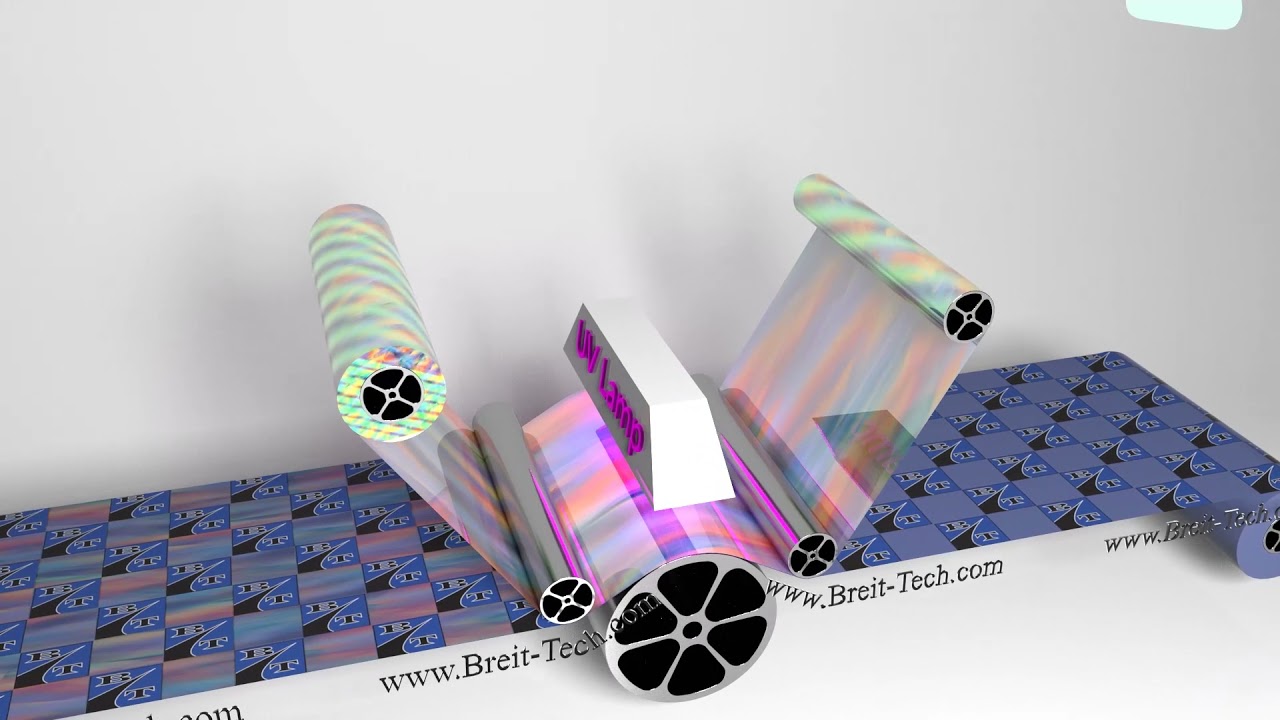

One such partner is Breit Technologies, the mastermind behind the Cast and Cure technology, which can be used to produce a range of holographic and other finishes on a wide variety of printed substrates.

This also includes the ability to add security features on the label itself. In addition, the textured effects add an extra dimensional tactile element to the finish, which means an interest for customers who pick up the product.

Solving problems

A decorative coating process that has been designed to retrofit to existing sheetfed and web presses – both narrow and wide web – Cast and Cure overcomes number of issues in product decoration.

First, the foil process itself does not affect recyclability or compostability of the substrate. It also provides a much more easy, less time consuming, and more cost effective method of creating shelf standout. The Cast and Cure effects are applied into existing varnish on any substrate – this therefore cuts out the need for the addition of a laminate film on the surface.

Add to this the comparative savings on energy costs used to apply a laminate film such as adhesive, and you can see the advantages adding up quickly.

Although Cast and Cure is ideal for packaging and labels, the process also works for a whole range of quality application. The relatively small investment in material costs and quick return on investment on the machinery needed to produce these fantastic effects, means that you can offer many patterns to customers, on many applications, for real added value.

Fast and flexible

The web fed casting units can be installed on a wide range of existing equipment, including offset, flexographic, gravure and further types of print machinery, with each unit is custom built.

In line units are rated to the speed of the equipment, so there is no impact on productivity. Off line units give the versatility to run rolls from multiple presses if required.

CyanX has an in-depth knowledge of the Cast and Cure application and its use, with regular customer demonstrations and advice to potential users.

How does it work?

An energy curable over print varnish coating is allied to a printed web and then cured, using either UV, UV-LED or EB curing stations. A web of Cast and Cure film is then laminated to the wet surface via a simple laminating nip station. The film’s micro-embossed surface imprints its pattern onto the coated surface.

As the desired effect is only achieved where the cast coating is actually applied, a wide range of designs from spot to flood coverage are achievable.

The film is then delaminated from the web and rewound, meaning that is can be reused, and reused, again. In fact, the company states that a roll can be used more than 20 times, saving a huge amount of waste.

The film is made from BOPP with no further additives or chemistry, and the material is 100% recyclable, whilst there are no VOCs involved in the process itself, and it is low energy, making Cast and Cure more environmentally friendly.

For more information get in touch with Josh Scanlan, sales executive, at CyanX. and follow us on Facebook, LinkedIn and Twitter

15th April 2024